This series of articles aims to set out key point of reverse osmosis, such as energy consumption, materials, design, cost, and operations.

Introduction

Reverse osmosis (RO) is a widely employed membrane separation technology for desalination and purification of water. The process plays a pivotal role in addressing the global water scarcity challenge, enabling the production of freshwater from saline sources. However, the efficiency of RO is intricately tied to the salinity of the feed water. This article will focus on feed water salinity, which exerts a profound influence on the energy consumption of RO systems.

Understanding Salinity in RO

Feed water salinity is typically quantified in terms of Total Dissolved Solids (TDS), which measures the concentration of dissolved ions and substances in water. High TDS values normally mean higher salinity levels. In the case or RO we normally only only talk about desalination, so we will focus on seawater salinity going forward. The presence of dissolved salts, minerals, and other solutes significantly increases the osmotic pressure of the water.

Osmotic Pressure and Energy Consumption

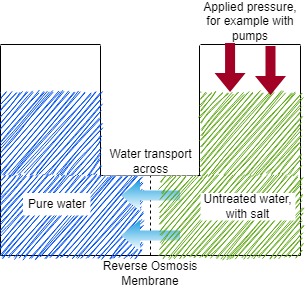

Feed water salinity relates to the energy consumption in RO through osmotic pressure. Osmotic pressure is the thermodynamic driving force governing the transport of water molecules through a semi-permeable membrane to equalize the concentration of solutes on either side. In simple words, water wants to have the same osmotic pressure everywhere. If you put a membrane in between two containers with freshwater and salt water in them, the water will transport from the freshwater side to the saltwater side, trying to equalise the osmotic pressure.

In RO, the primary objective is to overcome this osmotic pressure to desalinate the water. When the feed water is more saline, the osmotic pressure is higher. This means that a greater amount of hydraulic pressure must be applied to force water molecules through the membrane against the osmotic pressure. This pressure normally comes from electric pumps.

The osmotic pressure is directly proportional to the concentration of solutes in the feed water. Therefore, as feed water salinity increases (higher TDS), so does the osmotic pressure. This requires a higher energy input to counteract the osmotic pressure and facilitate water transport across the RO membrane.

Specific Energy Consumption and Feed Water Salinity

The energy required to overcome osmotic pressure and drive the RO process is quantified as specific energy consumption. Specific energy consumption represents the amount of energy consumed per unit of water produced. In RO, this parameter is directly correlated with the feed water salinity. As the feed water salinity rises, the energy needed to maintain a given water production rate also increases. This has several practical implications for RO systems:

- Operational Costs: Higher specific energy consumption leads to increased electricity cost to run the RO system. This has a high impact in applications where energy expenses are a significant part of total cost, like desalination plants.

- System Design: Higher salinity requires higher pressures to produce freshwater, which translates to equipment design needing to be suited for higher pressure applications. This involves more and often higher quality materials, increasing cost.

- Energy Efficiency Considerations: RO systems concentrate the salt in the remaining flow when they start removing freshwater through the membranes, which requires higher pressures later on in the system to keep producing freshwater. RO system designers must carefully consider the trade-offs between energy consumption and water production rates. Higher feed water salinity often necessitates lower recovery ratios, which means a larger portion of the feed water is rejected as brine to maintain water quality. This reduces the water recovery rate but conserves energy, although it also increases the total amount of water that requires pre-treatment.

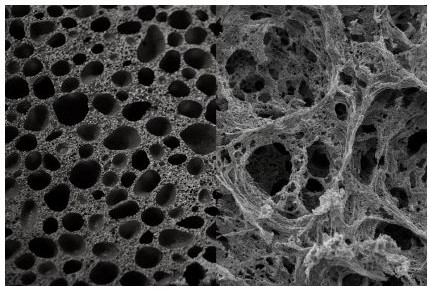

- Membrane Fouling: High feed water salinity can promote membrane fouling, which is the accumulation of salts and other impurities on the membrane surface. Fouling reduces water flux and increases resistance, demanding higher operating pressures and therefore more energy consumption. Effective pre-treatment can mitigate fouling effects to a large extent but membrane cleaning and the associated downtime is still required.

Reducing Energy Usage Due To High Salinity

To optimize the energy usage of RO systems to the feed water salinity level, different factors can be taken into account:

- Pressure Optimization: Changing the operating pressure is one way to mitigate the effects of high feed water salinity. Higher pressures can overcome greater osmotic pressures, but can also cause a larger impact from fouling as the increased pressure blocks the membrane pores faster than a lower pressure with a lower associated freshwater production.

- Membrane Selection: The choice of RO membrane material and properties is critical for overall performance. High-quality membranes with low resistance and good rejection properties demand less energy. Recent advancements in membrane technology have led to more energy-efficient options. See our Academic and Technical Resources for the most recent developments.

- Energy Recovery Devices: The implementation of energy recovery devices, such as pressure exchangers or isobaric devices, can help recover and reuse some energy from the waste (brine) stream. These devices can improve the efficiency of RO systems by around 25% as a minimum.

- Pre-Treatment: A well designed pre-treatment plant is essential to remove impurities, suspended solids, and fouling agents from the feed water. Effective pre-treatment can reduce energy consumption by minimizing membrane fouling.

- Operational Control: Maintaining optimal operational parameters, including flow rates and recovery ratios, can help minimize energy consumption while ensuring the desired water quality.

Temperature Effects in RO

In addition to feed water salinity, temperature also plays a role in the energy dynamics of RO. Temperature influences the physical properties of water, affecting its viscosity and density. In RO, operating at higher temperatures can reduce water viscosity and increase water permeability. It is important to note that this effect is limited in seawater RO due to the dominance of osmotic pressure in the energy usage equation. Additionally, higher temperatures usually cause an increase in the solubility of salts which can lead to a slightly lower removal rate.

Concluding Remarks

The energy consumption of reverse osmosis systems is intricately linked to the salinity of the feed water. High salinity levels result in elevated osmotic pressure, which necessitates higher energy inputs to facilitate water transport across the membrane. Understanding the technical details of this relationship is essential for optimizing the energy efficiency of RO systems.