Two widely used filters, disc and drum filters, are popular in industries from aquaculture and wastewater treatment to chemical processing. These two types of filters are some of the most basic filter types, but have been developed to deal with a wide range of conditions and inputs. In this article we will discuss the operating principle and common (and some uncommon) uses of Disc Filters.

Want to know more about Drum Filters? Find our article here!

Disc Filter Working Principle

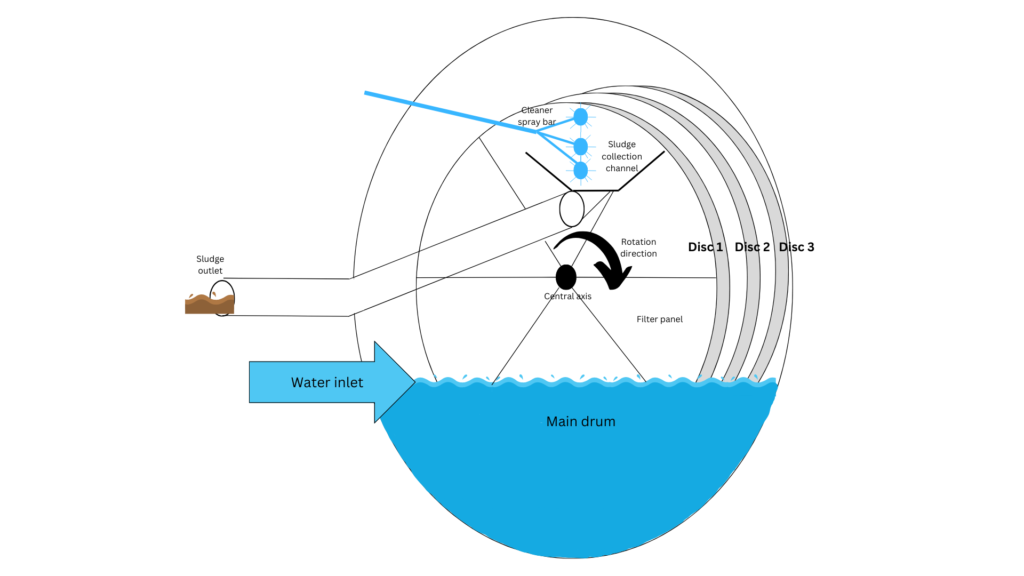

A disc filter consists of a large tank with multiple rotating discs inside. Disc filters operate by the same principles as rotating drum filters, although they have a higher surface area for their footprint.

The filter has a similar base tank to a drum filter, into which water is pumped, and the level is maintained by an outlet valve. Multiple screens that remove solids from the flow are around disc-shaped frames, usually made of aluminium, steel, or plastic.

The water flow travels through the discs, either from outside to inside or from reverse, and the solids stay behind against the filter panels.

Disc Filter Detailed Operation

A disc filter consists of a large half-open or fully enclosed tank with multiple sets of filter discs inside it, standing up vertically. As the water enters the drum through the central pipe, it ends up on the inside of one of the filter discs. The filter discs let the water flow through them, but retain the solids that don’t fit through the filter panel pores. The water then enters the main drum and

A great video showing a disc filter in operation can be found here and a clear animation here.

Disc Filter Inside Out

In some industries (usually not the water industry) it is important to collect sludge with the highest concentration of solids possible. For these applications, the disc filter is used ‘inside out’, which means the sludge cake will collect on the outside of the filter screens. The sludge cake can then be removed by a scraper on the outside of the discs, after which it can be processed further. The treated water is now collected from the inside of the drum rather than the outside. The video above shows this operational variant.

Disc Filter Control

A number of parameters control disc filters while in operation, and these must be chosen carefully for optimum operation and to avoid unnecessary shutdowns. Disc filters are normally controlled based on the internal level: a rising level means that the filters are not allowing enough water through.

- Disc Rotation Speed: The speed at which the filter discs rotate is critical for maintaining a consistent flow of liquid through the filter panels. The rotation speed can be adjusted to control the filtration rate.

- Pressure Differential: The pressure differential or pressure drop across the filter is an important parameter. It is the difference in pressure between the inlet and outlet sides of the filter. The driving factor is the level differece between de inlet and the outlet.

- Filter panels: different pore sizes can be selected which influence the minimum size of the solids that are removed but also influences how quickly the filter panels fill up with sludge.

- Filtration Rate: The rate at which the liquid is passed through the filter should be adjusted to achieve the desired level of filtration.

- Particle Size and Characteristics: Understanding the size and nature of the particles you are trying to remove is crucial. It helps in selecting the appropriate filter media and operational parameters for efficient filtration.

- Pre-Filtration: Depending on the quality of the incoming liquid, pre-filtration may be necessary to remove larger debris or protect the disc filter from excessive fouling. In some industries, such as aquaculture, it is important to control the amount of fats and proteins that reach the disc filter to avoid clogging up the filter screens.

Disc Filters In The Water Industry

Disc filters are used in the treatment of wastewater, the pretreatment of agriculture water especially when taken from surface water, and widely in the treatment of produced water in the petrochemical and mining industries. Their main benefits are the filter panel pore size selection, allowing for accurate removal of solids, and their straightforward control systems.

Limits of using Disc Filters in the water industry are:

- High sludge volume produced.

- Maintenance more costly than stationary filters.

- Many units needed to replace large-scale settling tanks or media filters.

[…] Want to know more about Disc Filters? Find our article here! […]