A Moving Bed Biofilm Reactor (MBBR) is an uncommon type of bioreactor that use 3D structures to grow biofilms of bacteria which clean a variety of types of wastewater. This type of bioreactor can be used for wastewater treatment and is one of the major technologies enabling nutrient reuse from wastewater.

MBBR Technology – Biofilms

The basics of MBBRs do not involve technology, but is focused around biofilms. Biofilms are essentially a community of microbes that are bound together by a layer of biological polymers, also called slime. These communities usually form when bacteria (and fungi) are provided with a growth medium and favourable conditions. Due to these conditions, the colony of microbes can expand and grow quickly. In an MBBR, the growth of these biofilms is promoted by using a plastic 3D structure on which the bacteria can settle.

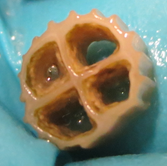

This image shows a typical MBBR carrier unit, which is built from plastic and has a high surface area. The biofilm can be seen clearly in the centre cross of the carrier.

Image credit Pesten, CC BY-SA 4.0, via Wikimedia Commons

Nutrient Reuse

Growth of bacteria and other microbes is the start of nutrient collection and transformation, with some of the biological matter broken down or consumed by the organisms, and part of it stored as biomass. This opens the door to recovery and reuse of these nutrients, as the created biofilm usually has a much higher solids percentage than sludge when it is removed from (urban) wastewater.

Nutrient reuse is a key future goal for the wastewater industry for two reasons:

- To prevent excess nutrients washing into surface water such as lakes and seas. This is important to reduce nitrification and other effects of excess nutrients, which lead to mass death and ecosystem change in coastal waters and lakes.

- To recycle essential nutrients such as phosphorus and some salts. Phosphorus is an essential element for tissue growth and is therefore required for agricultural applications. The main issue is that phosphorus reserves are severely stressed and limited, risking depletion in a few decades.

For more technical info on phosphorus and its removal from wastewater, read our article about it or see this MIT summary!

MBBR Process

The Moving Bed Biofilm Reactor process is fairly straightforward, and is very similar to the widespread activated sludge process.

The treatment water is brought into contact with a highly active organic colony, growing on the carrier units or medium carriers. These carriers float around freely, and high-rate aeration is supplied to the treatment water to ensure effective oxidation. The resulting sludge is settled in clarifiers and can be processed using anaerobic digestion or other standard methods.

Design and Control Parameters

MBBR design is very similar to the classic activated sludge process: both usually comprise large rectangular tanks with aerators at the bottom that introduce small air bubbles into the tanks. The living media in MBBRs is comparable to the activated sludge process, although the colony forming characteristics of the bacteria and fungi is not expressed in the activated sludge process due to the lack of growing medium.

Usually, the effluent water of the MBBR is clarified to remove sludge – which is sent for further processing – while the effluent water can either be recycled for process use or sent for discharge. Some companies, such as Ecologix, use an optional activated glass filters as a secondary filtration step after the clarifiers to ensure low solids loading in the final effluent.

Operational control of an MBBR is similar to an aerated activated sludge process unit. Some of the main process indicators that are checked are the biological and chemical oxygen demand (BOD & COD) and dissolved oxygen. A number of sludge indicators are the following:

- Sludge volume index: the volume of sludge that settles from a mixed sample in a set amount of time, divided by the total amount of sludge in that sample.This indicates how much of the sludge in the unit can be removed by settling for that set amount of time.

- Mean cell residence time: the amount of solids in the tank at any time divided by the total outflow of waste solids per day, which indicates the residence time of the solids in the process.

These indicators are influenced by only two main parameters: treatment water flow through the reactor, and aeration rate or airflow through the aerators into the tank. These will influence the total residence time and the available oxygen, which are the only key parameters influencing the process by changing the available nutrients and time for the bacteria to remove solids.

Alternative Uses of MBBRs

Moving Bed Biofilm Reactors can be used in various industries. Although the focus here has been on wastewater processing due to its similarity to regular activated sludge treatment, other industries in which MBBRs can be used are:

- Chemical industries where biofilms are used;

- Food and Beverage processes where fermentation or colony growth (such as yeasts) are used;

- Aquaculture, where sludge is aerobically processed;

- Dairy processing, e.g. where bio cultures are used (e.g. yoghurt).

MBBR Concluding Remarks

Moving Bed Biofilm Reactors are a versatile type of reactor that can be used in a range of industries. Most notable is its use in wastewater treatment as this type of reactor can intensify the activated sludge process by reducing the footprint required for the process, and improving final effluent quality compared to comparative processes.

Hello there! Do you know if they make any plugins to help with Search Engine

Optimization? I’m trying to get my blog to rank for some targeted keywords but

I’m not seeing very good gains. If you know of any please share.

Many thanks!