Two widely used filters, disc and drum filters, are popular in industries from aquaculture and wastewater treatment to chemical processing. These two types of filters are some of the most basic filter types, but have been developed to deal with a wide range of conditions and inputs. In this article we will discuss the operating principle and common (and some uncommon) uses of Drum Filters.

Want to know more about Disc Filters? Find our article here!

Drum Filter Working Principle

A drum filter is a simple type of filter that uses a rotating drum to remove solids of a certain size from the incoming flow. In the case of wastewater treatment, they are normally used to remove smaller solids such as sand.

The drum filter is constructed by lowering a round drum, covered in filter screens, into a large tank. The inlet of the filter leads the treatment water into the inside of the drum, where it drains downward through the filter panels. Any solids larger than the screen size of the drum filter are captured and left behind.

Drum Filter Detailed Operation

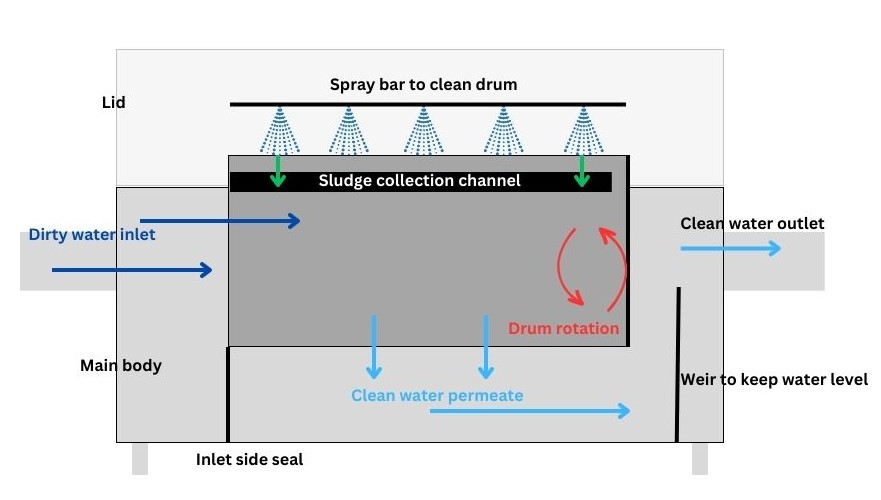

A drum filter consists of a main body (a tank) with a rotating drum inside. The untreated water comes in through a small inlet tank and enters the center of the drum, where the water level sits about halfway the height of the drum. The only route for the water to take is through the filter screen, since the right side of the drum is blocked off by a seal. The solids stay behind in the screens, and as the screens fill up with solids they become blocked and let less water through. This causes the water level to rise inside the filter, which trips a level sensor, turning on the spray bars and letting the drum rotate. The spray bars clean the screens by spraying water on it, usually between 5 and 10 bar (72 to 145 psi) at the nozzle. The high velocity of the water sprays the solids off and into a sludge collection channel, which

A schematic view of a drum filter shows the inlet to the drum, the drum itself with the filter screens, and the main outlet through the bottom of the drum. The top shows the spray bars which spray the cake of solids off the screens and into the sludge collection channel.

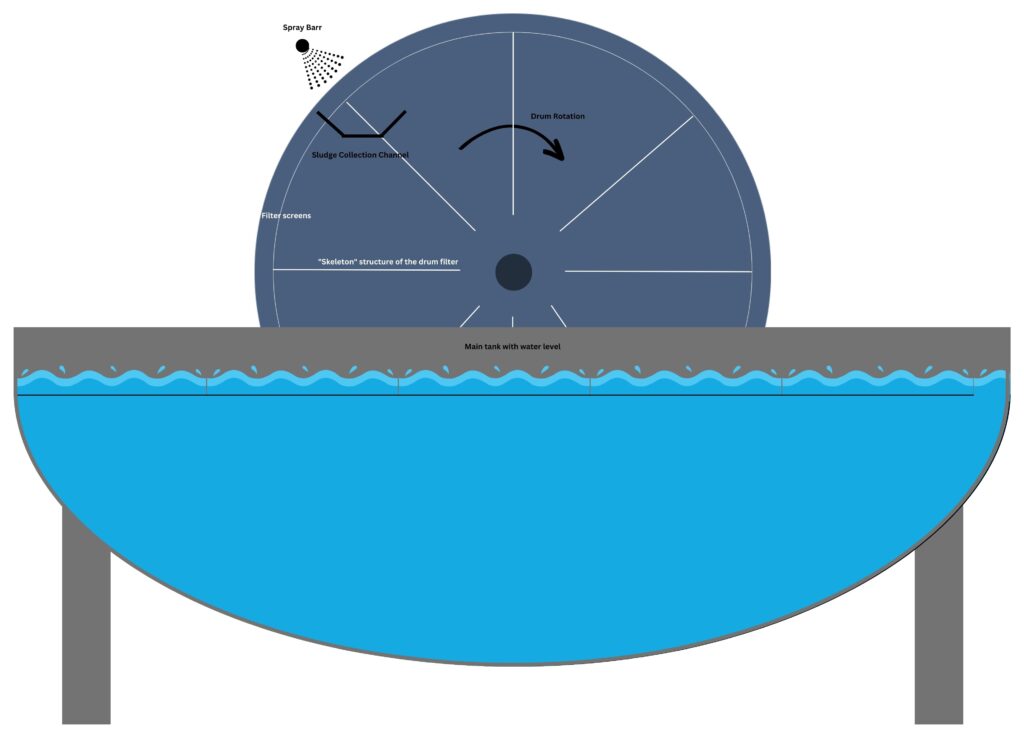

The image above shows a schematic sideview of a drum filter, showing the water level at the drum, the central axis and support beams, the screens (lighter circle) and the direction of rotation.

A great video showing a drum filter in operation can be found here.

Drum Filter Inside Out

In some industries (usually not the water industry) it is important to collect sludge with the lowest concentration of solids possible. For these applications, the drum filter is used ‘inside out’, which means the sludge cake will collect on the outside of the filter screens. The sludge cake can then be removed by a scraper on the outside of the drum, after which it can be processed further. The treated water is now collected from the inside of the drum rather than the outside.

Drum Filter Control

As described above, drum filters are normally controlled based on the internal level. The level in the main tank, inside the drum, tells the operator how much water is coming in compared to the outflow, and whether the screens are clean or blocked. If the internal level rises during startup, the inlet flow is higher than the maximum outflow which means the inlet flow should be decreased.

During steady-state operation, an increasing level in the drum means that the screens are blanking (becoming full of solids), which trips the drum rotation and the spray bars. Since this produces sludge in the sludge collection system, it is normally preferred to not have the drum rotating and the sprays on continuously, although this is possible.

Drum Filters in the Water Industry

As mentioned, Drum Filters are used widely in many industries. In the water industry, they are used for both drinking water and wastewater treatment, although their use in the latter is limited. Using Drum Filters removes solids in a predictable way, and operation is easy due to easy cleaning. This gives them an advantage in the processing of water with high solids loading. Drum Filters can be fed by gravity or pumped feed, as long as the level inside the tank is controlled carefully to avoid spills.

Limits of using Drum Filters in the water industry are:

- High sludge volume produced.

- Maintenance more costly than stationary filters.

- Many units needed to replace large-scale settling tanks or media filters.

[…] Want to know more about Drum Filters? Find our article here! […]