Dissolved Air Flotation (DAF) is a water clarification technology that is often used in wastewater treatment. This article discusses the underlying principles, equipment design, operations, and control of DAF equipment.

Please visit our other DAF article for the short version of the information below, which can be used to understand DAF design and operation in a more simplistic way.

DAF in short

Dissolved Air Flotation works on the principle of letting air, dissolved in water under pressure, form micro bubbles (10-50 micron) at the bottom of a tank. The microbubbles rise up to the surface, and as they form and grow, the bubbles take oil, greases, and small solids with them. The physics of this process are described below.

For a more basic overview of dissolved air flotation and its uses, see our basic guide to DAF.

Dissolved Air Flotation System Layout

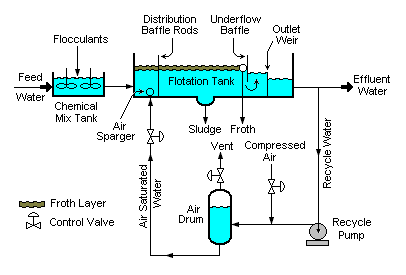

DAF units usually consist of the following units, as represented in the diagram below.

Image credit mbeychok, CC BY-SA 3.0 <https://creativecommons.org/licenses/by-sa/3.0>, via Wikimedia Commons

- Optional: feed mixing tank to dose flocculants, for small solids that are more readily removed after flocculation. See our article on water treatment basics or our dictionary for more information about flocculation.

- Flotation tank: this is the main tank where organics removal happens. The air sparger at the bottom of the tank allows the water with dissolved air to enter the tank, while the inlet valve allows a pressure drop, causing the air to come out of solution. The foam layer at the top contains the removed pollutants, which is removed for external processing. Distribution baffles ensure even and water distribution, while the underflow baffle stops the foam from spilling over into the clean side of the tank. A final outlet weir forces the level in the tank to stay sufficiently high to allow good distribution.

- A sludge removal drain or channel at the bottom of the tank removes any heavier solids that may settle despite the constant upward push from the bubbles.

- The effluent water is sent for further processing, while the recycle water is pumped at pressure against the control valve that can be seen just before the recycled water enters the tank on the left side of the diagram.

- Pressurised air (or pure nitrogen for explosive substances) from an external source such as a compressor or tank is added to the now-pressurised water stream. The combined stream is sent to a pressurised separation tank or air drum (optional) to remove any air that is not dissolved due to the water being over-saturated. This prevents any bubbles stopping the flow, causing air lock. A pressure control valve allows air to vent from the top.

In the past, the entire inlet flow was pressurised so that air could be added to it, with bubbles forming throughout the bulk of the water after depressurisation. This has in recent years (from ~2000) been replaced by recycle flow only systems, in which only a part of the water is recycled to form whitewater (water with dissolved air). - The control valve allows the pressure to drop, and the air sparger at the bottom of the tank maximises microbubble formation and evenly distributes the flow.

Physics of DAF

Dissolved Air Flotation is a fairly simple technology using pressurised air to remove small solids, oils, and greases from wastewater. The physical process happens as follows:

- Pressurised air is mixed with pressurised water. Due to the higher pressure, more air is able to dissolve into the water. Pumps with a high energy output are able to achieve complete air saturation of the water.

- The pressure control valve causes the high pressure to drop to low. The resulting drop in pressure means that the water is now suddenly over-saturated (supersaturated) with air.

- The excess air molecules start to cluster together at existing nucleation sites such as small particles or longer-chain molecules, or surface-active molecule. Since the water is supersaturated instantaneously, the clusters of air molecules stay small, forming very small bubbles.

- Buoyancy now causes the bubbles to rise, taking the contaminants with them. Generally, the surface tension of the water keeps particles incased in bubbles once they reach the top of the tank, causing a foam to form which can be easily removed.

DAF operation and control

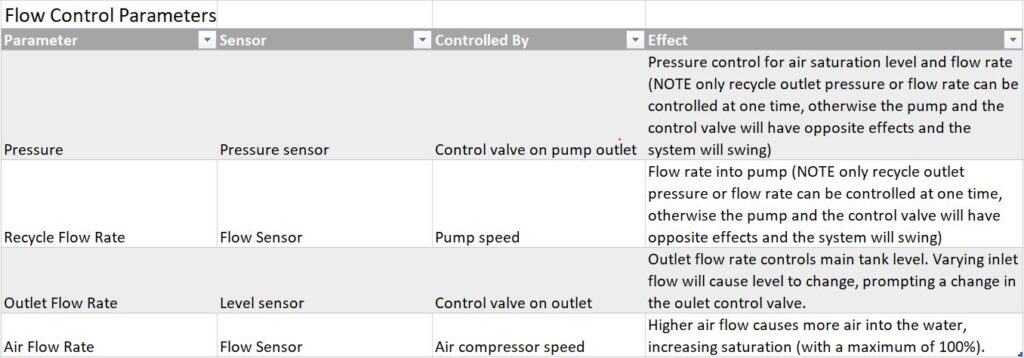

DAF systems depend on fairly simple but sensitive control to allow for maximum removal of pollutants from the inlet flow. In the main tank, water level and recycle flow are the key parameters that determine removal efficiency. Pump operation requires a suitable air flow, pressure, and recycle flow for maximum air saturation of the recycled water flow.

The main tank level is controlled by the rates of outflow and recycle flow. This requires finetuning to ensure that, if the recycle flow rate changes, so does the effluent flow rate (i.e. higher recycle requires lower outflow and vice versa). Usually the pump control system is in charge of the recycle flow, which means the effluent outflow needs to be controlled separately or linked to the pump system control.

Generally, DAF systems allow for manual setting and tuning of the control parameters. Like other wastewater systems, DAF systems usually deal with fairly consistent quality wastewater at a consistent flow rate. This does not require automated tuning of the control parameters but instead relies on operators setting the correct parameters for long term operation followed by monitoring of process parameters. The table below contains a quick overview of the control parameters for DAF units.

Sensors

DAF uses a multitude of sensors for its control. Pump skids are usually controlled by a flow meter, outlet pressure sensor, and air flow meter. This gives full control of the recycle flow and the air saturation level. The main tank is controlled by the outlet control valve for the recycle flow and the outlet valve for the main flow. The main inlet pipe is usually just an open connection since it is not pressurised.

Further Reading

An interesting article on bubble formation and nucleation can be found here (open Chapter 1 and Chapter 2): Virginia Tech, Robert P. Scardina.

A paper on using DAF for the removal of dispersed oil and surfactants from water can be found here: https://doi.org/10.1016/S0927-7757(02)00208-X.

More details on different types of DAF units and their uses and operation can be found through ESI.info.

Evoqua Water Technologies has an interesting paper on design paramenters and factors for DAF systems which can be found here: Advances in DAF systems.

Concluding Remarks

DAF is a versatile technique for the removal of a different variety of macropollutants from wastewater and other water flows. It is widely used in the petrochemical industry where it aids in the removal of leftover oils from produced water before discharge.

Featured image credit Enviplan, CC BY-SA 4.0 <https://creativecommons.org/licenses/by-sa/4.0>, via Wikimedia Commons

What a information of un-ambiguity and preserveness of

valuable knowledge about unpredicted feelings.